Optional accessories & upgrades

Following items are optional accessories and upgrades to the instrument.

Dual solvent cleaning

A suitable solvent used for cleaning should have the following two main characteristics:

- It should be able to dissolve the sample that was tested, i.e. clean the tube completely

- It should evaporate quickly enough at the bath temperature so that the tube is fully dry after cleaning

If the solvent used does have the ability to dissolve the sample, but does not evaporate quickly enough, a second solvent can be used to rinse out the first solvent, as well as dry the tube. Usually, low boiling solvents are used for this purpose, such as Acetone or MEK.

Cooling spiral & cooling circulator

For measurements close to ambient (± 8°C), an additional cooling circulator is required to create sufficient offset for the temperature control unit. Each bath needs to be fitted with a cooling spiral, to which an external cooling circulator can be easily connected. Complete with tubing and fittings. Cooling spiral and cooling circulator will be supplied separately on request.

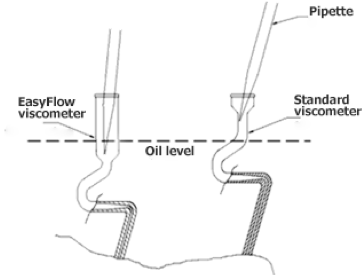

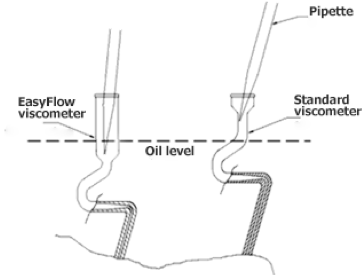

EasyFlow viscometers tubes

For high viscosity, EasyFlow can be great use. EasyFlow viscometers can be provided starting from tube constant 1.0.

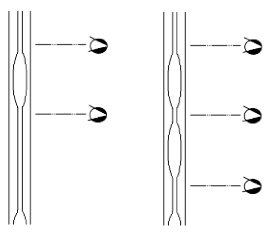

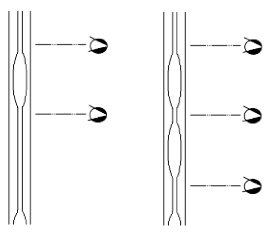

Single Duplo

Duplo measurement tubes

The optional duplo measurement upgrade adds another array of optical fibers to the instrument, bringing the total number of detection points to three per tube instead of two. Together with adapted S-flow tubes, which are fitted with two measuring trajectories, this enables the S-flow 870, S-flow 1250 and the S-flow 3500 to perform duplo measurements with a single sample injection, increasing productivity, saving even more on solvent consumption and runtime.

Compressor

Omnitek S-flow systems operate on clean and dry 5 bar @ 5 l/min of compressed air. A suitable compressor can be supply from Omnitek if no compressed air is available.

Positive - displacement pipette

Air-displacement pipette is supplied with S-flow series as a standard. It is recommended to use positive displacement pipette especially at higher viscosities (300 mm2/s and above) to avoid operator errors and for more accurate and repeatable injections.

Software

All Omnitek S-flow systems utilizes advanced and easy to use multi-lingual software, it can be operated directly from the touchscreen, and both calibration and viscosity measurements can be performed without PC or software. However, to have more control, dedicated software is available, which can be used to control multiple systems.

PC

A PC system can be sourced locally or through Omnitek. Omnitek supplies the latest model entry level laptop or, if required, desktop. When sourcing locally, make sure the operating system is Windows 7 or later and that the PC/Laptop has 1 free USB port per instrument.

Printer

Any kind of printer can be used if instrument is connected to a PC via software. A printer can be sourced locally or through Omnitek. Omnitek supplies the latest model entry level laser printer.

Robotic Operation

Omnitek offers “Robotic Operation” for models S-flow 1250 and 3500 for customers that run large numbers of samples (>500 samples per day) and want to automate their sampling process. As each laboratory will have its own requirements, automation is a highly customized product which requires elaborate preparation. Please contact us for specific solutions to your sampling needs.

ASTM Thermometers

All S-flow units can be equipped with ASTM thermometers. The recommended thermometers that can be supplied are the modern digital contact thermometers (DCT), used at multiple temperatures.